How to select your right led uv curing system for your press work ?

How to select your right led uv curing system for your press work ?

Before selecting a suitable led UV curing system , we should confirm information of the adhesive, material substrates ect.

Typical information required to aid the selection of a suitable UV led curing system

UV led glue, uv led ink, uv led paint or their uv sensitive materials are necessary.

1,wavelength in nm

2,Maximum processing temperature

3,Your printer running speed.

4, light intensity / density / MW value (maximum value of energy per unit area, ?W/m2) / MJ (distance, speed, time, How much power per square meter , ?W /m2 )

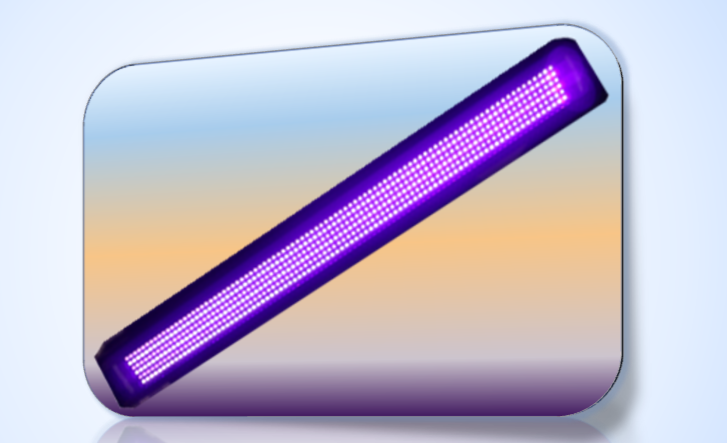

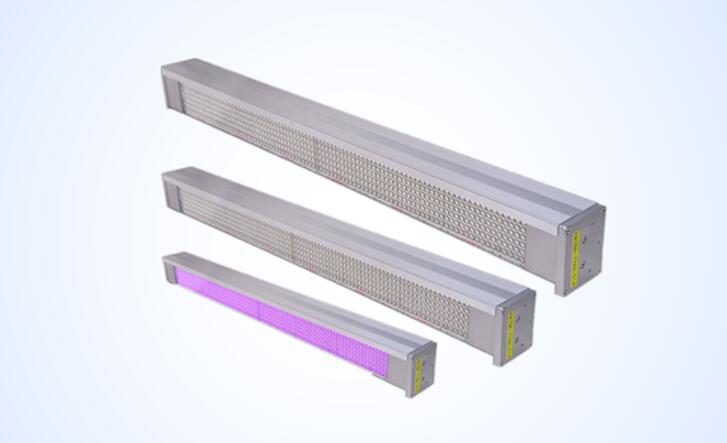

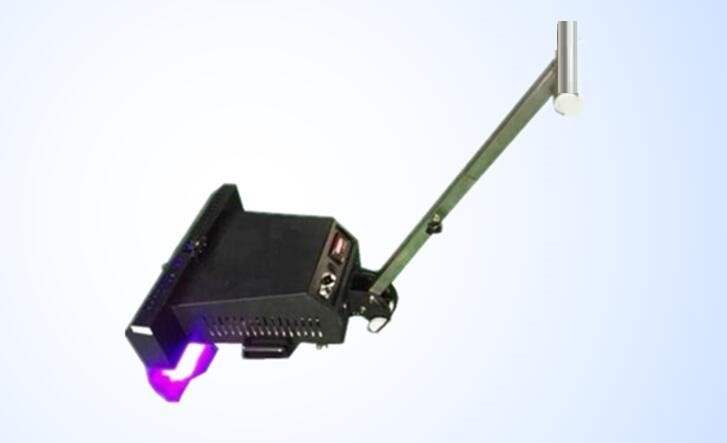

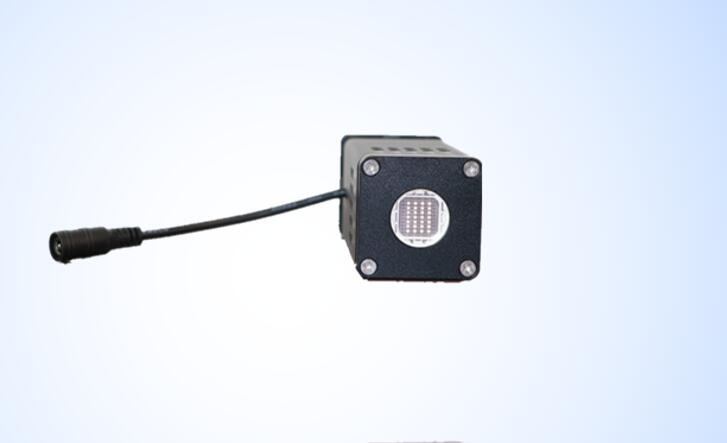

5, uvled curing lamp size requirement.

6, application distance

Advantages

1.Extra-long life: 25000h~30000h .

2.Energy saving: save 80% electrical energy than Mercury lamp .

3.Clearly reduced exposure to noise of the line operators since no exhaust system is necessary.

4.Environment friendly: NO mercury. NO Ozone.

5.Instant on/off without waiting times.

6.Low temperature.

7.Less danger of uncured photo initiators.

8. Stepless adjustment of the specific lamp power from 20 - 100 %.

9.Multiple control modes :Constant current and voltage, pedal control, intelligent optical and manual modes.

10. Reduced risk of fire on UV lines, possibly reduced insurance premium.

11.Low VOC.

How to choose the uv led curing system ?

1,Select the size of emitting window according to your material length.

2,Select the peak irradiance according to your ink wavelength.

Any wavelengths, sizes and irradiance can be customized, and more high-power UV-LED can meet your requirements.

UV curing system can be used for curing uv ink, uv glue, uv adhesive, uv paint, uv varnish or any other UV sensitive materials. And the wavelength depends on the uv sensitive material which you use. Usually the uv glue and uv adhesive need 365nm. UV ink, uv paint and uv varnish need 385nm, 395nm or 405nm.