LED UV cure light devices uv led ink drying system

LED UV cure light devices uv led ink drying system

LED UV cure light devices uv led ink drying system

UV LED cure light devices are capable of emitting a narrow spectrum of radiation (+/- 10 nm), while mercury lamps have a broader spectral distribution. Fluorescent ultraviolet lamps can be fairly narrow, although not as narrow as LEDs.

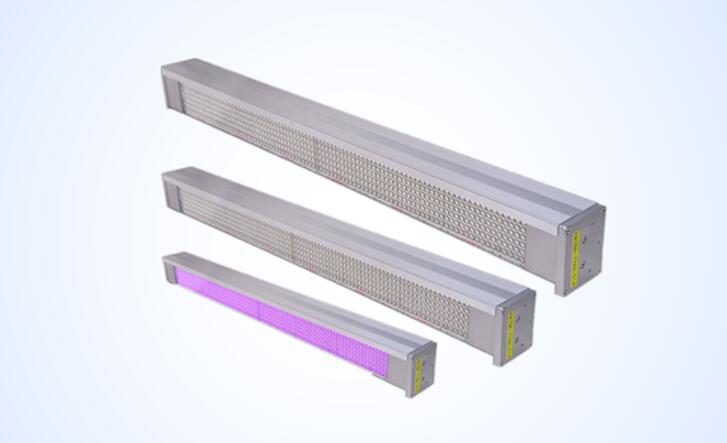

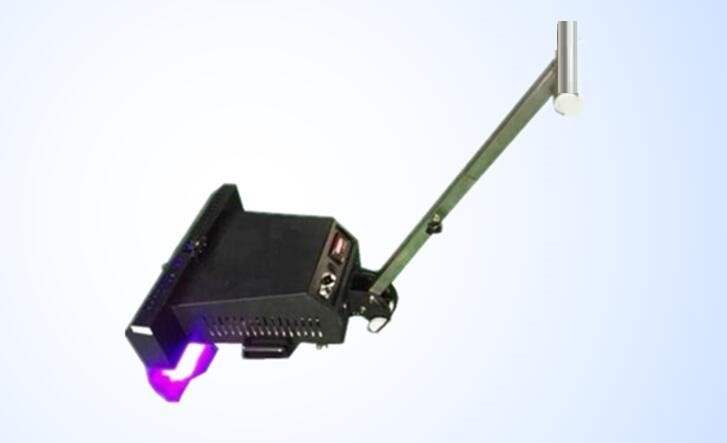

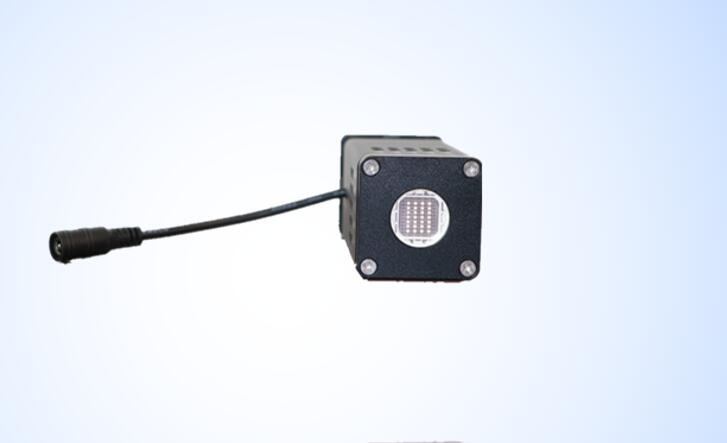

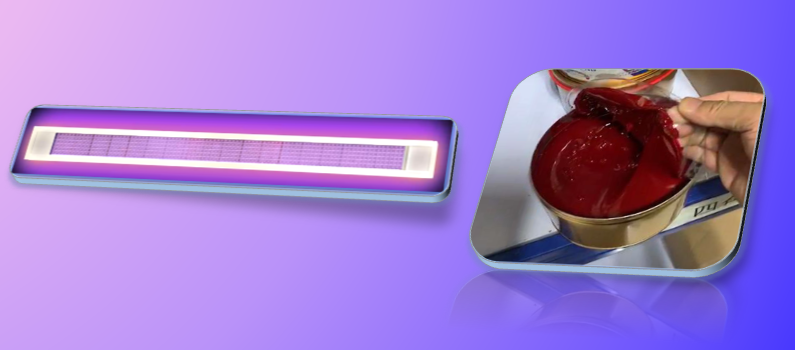

LEDs are much more expensive but last up to 10 times longer running time and unlike fluorescent tubes, can be cycled on and off frequently as they require no startup or cool down period. While they can not produce the same spectrum as mercury vapor or fluorescent tubes, photoinitiators can be formulated to work with them easily. Only led has got the same wavelength with the relative ink, they will cure rapidly and save electricity power . Further more , they don't emit any Hazardous substances, such as ozone . and no any VOC . Other advantages of UV LED curing systems are the ability to be more compact, the ability to work with heat-sensitive substrates, better energy efficiency and improved safety comparing to mercury lamp.

UV LED Curing Systems

UV LED curing is a relatively new technology that changes a liquid into a solid using ultraviolet (UV) energy. When the energy is absorbed, a polymerization reaction occurs that transfers the relative wavelenth ink material into a solid. This new technology process happens instantaneously, making led uv light devices alter to conventional time to a new peroid , led uv period.

With more appication of UV LED curing system in reality, it has become more common due to the multitude benefits that led uv curing system offers.

Benefits as below:

1 ,Increased Efficiency

2. Multi-applications.

3. Complete Environmentally Friendly.

4, Ensured Safety

5. Long Life Service

6. High-End Functionality

7.Well-Suited for Heat-Sensitive Substrates

8.Uniform radiation of the lamps across the entire working width.

9.Clearly reduced exposure to noise of the line operators since no exhaust system is necessary.

10. Stepless adjustment of the specific lamp power from 20 - 100 %.

11.Instant on/off without waiting times.

12. No waste disposal of old UV lamps containing heavy metal (GA, Hg).

13. No exposure to ozone of the line operators.

14. Excellent penetration of the UV radiation allowing for good adhesion, also with pigmented lacquers.

15. Less danger of uncured photo initiators.

16.Reduced risk of fire on UV lines, possibly reduced insurance premium.

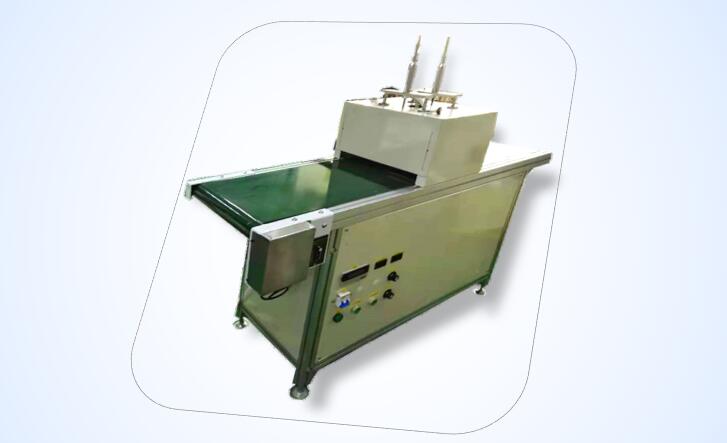

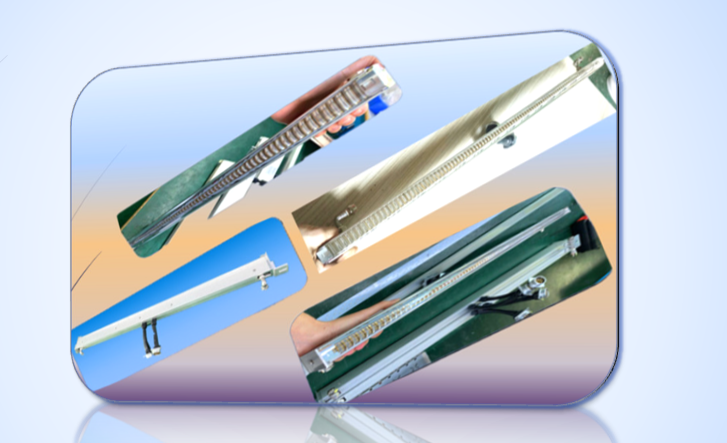

Youwei led uv solution company provides extensive UV LED curing experience, product knowledge, and technical expertise. we focused on led uv curing system for Heidelberg / Roland / KBA / Komori offset printing application,in the meanwhile we also offer led uv machine for wooden flooring /furniture finishes /painting work, led uv torch for car repairs job, led uv lamp for flatbed /inkjet /silkscreen printing cure, as well as the supporting led uv ink for offset printing.