LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg description and specification

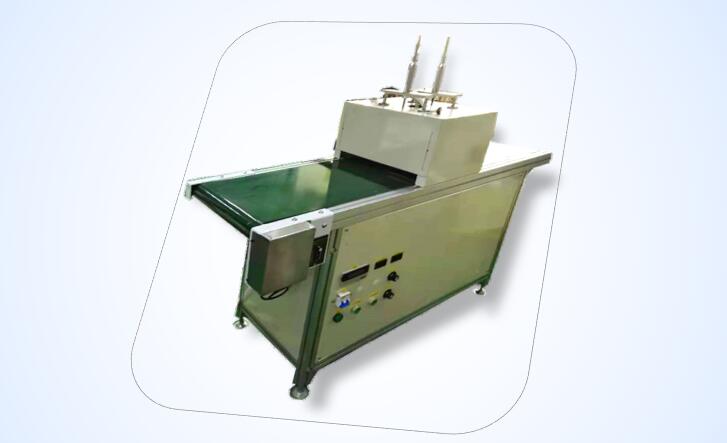

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg system picture

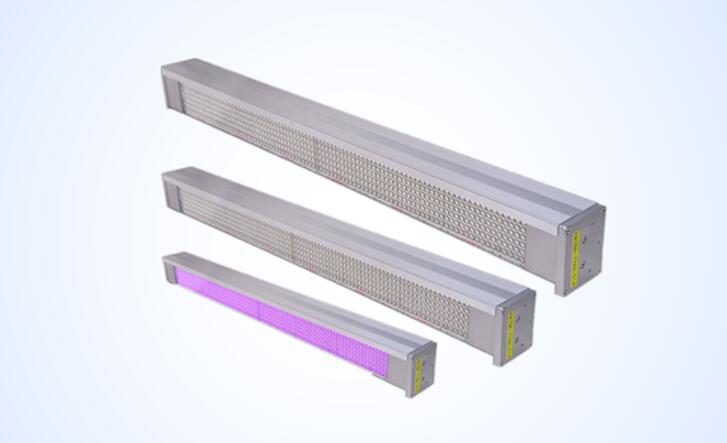

Shenzhen Youwei Printing Material Equipment Co.,Ltd. group manufacturers diffferent size LED-UV for sheetfed offset printing, with ready-to-go solutions for 20", 26", 30" and 40" press widths, and custom solutions for any other specified width of press, such as Heidelberg, Manroland Lithrone, KBA, Komori, Ryobi, etc. Our LED UV offset printing systems to the sheetfed offset printing industry proven to been the best reasonable led uv curing solutions in this offset printing field. and we have installed and supported more LED-UV systems than you can imagining. Meanwhile, we also have led uv ink factory specidaly services to all kinds of offset printing paper/PVC/PE material.

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg system contents as below picture showing

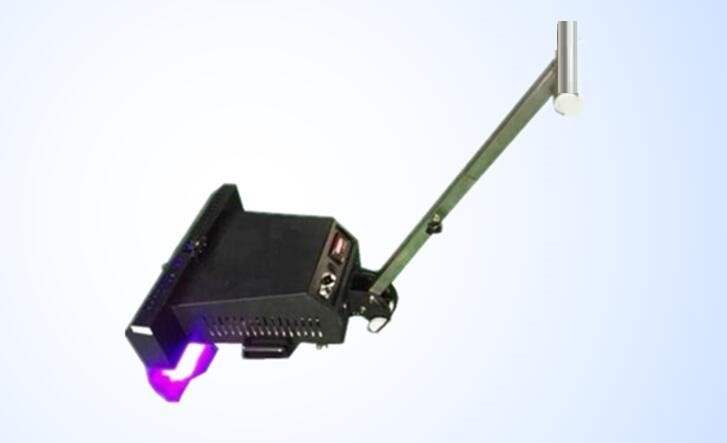

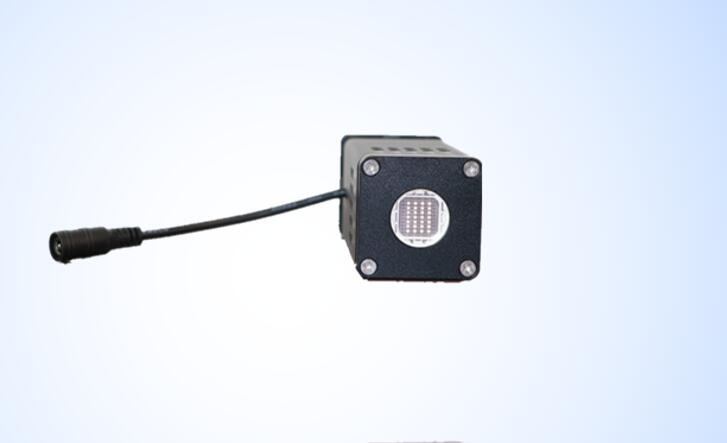

This LED-UV for Sheetfed Offset Printing solutions consists of one main electronics controlling panel, one chiller, seven led uv lamps , one conventional uv lamp, this solutions is desinged for offset 8 colors +1 coater pritning application. Suitable for morst normal offset printing, paper / pvc /pe application.

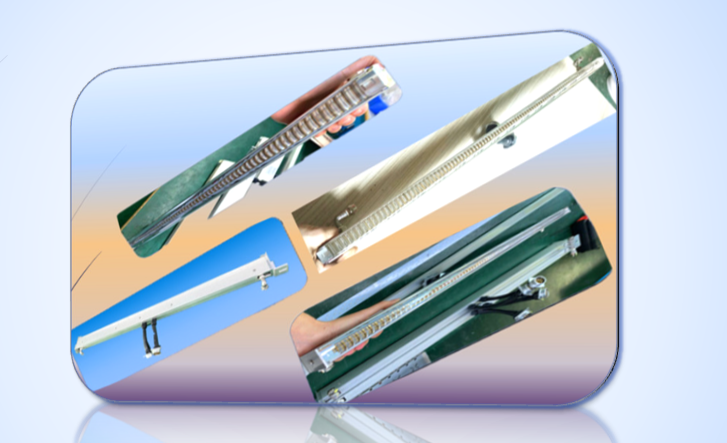

Deffient solutions support customers's different requires. Meet seperately requirement, such as diferent speed from 5000-18000 sheet/hours. wavelength from 365nm-415nm, deponding on clients different printing demands.

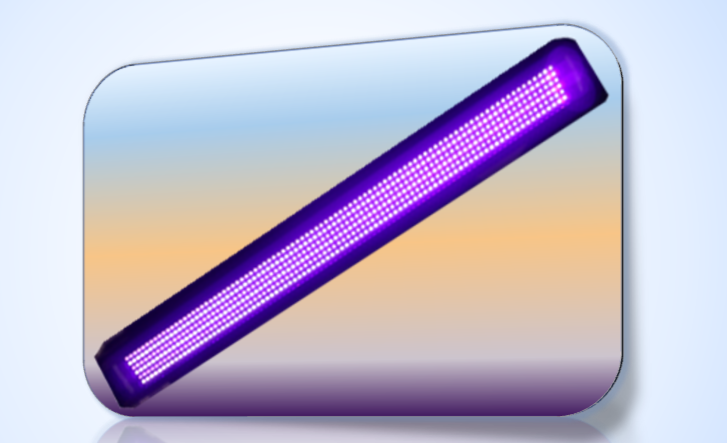

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg solutions with Multi-wavelength lamps picture

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg installation picture as below:

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg application

LED-UV for Sheetfed Offset Printing UV LED Curing Heidelberg Print Benefits as below:

1 ,Increased Efficiency

2. Multi-applications.

3. Complete Environmentally Friendly.

4, Ensured Safety

5. Long Life Service

6. High-End Functionality

7.Well-Suited for Heat-Sensitive Substrates

8.Uniform radiation of the lamps across the entire working width.

9.Clearly reduced exposure to noise of the line operators since no exhaust system is necessary.

10. Stepless adjustment of the specific lamp power from 20 - 100 %.

11.Instant on/off without waiting times.

12. No waste disposal of old UV lamps containing heavy metal (GA, Hg).

13. No exposure to ozone of the line operators.

14. Excellent penetration of the UV radiation allowing for good adhesion, also with pigmented lacquers.

15. Less danger of uncured photo initiators.

16.Reduced risk of fire on UV lines, possibly reduced insurance premium

More led uv for offset printing services visit here

LED-UV for Offset Printing Business quick reply, contact at below: