Precautions for UV varnish- how to use uv varnish correctly

Precautions for UV varnish- how to use uv varnish correctly

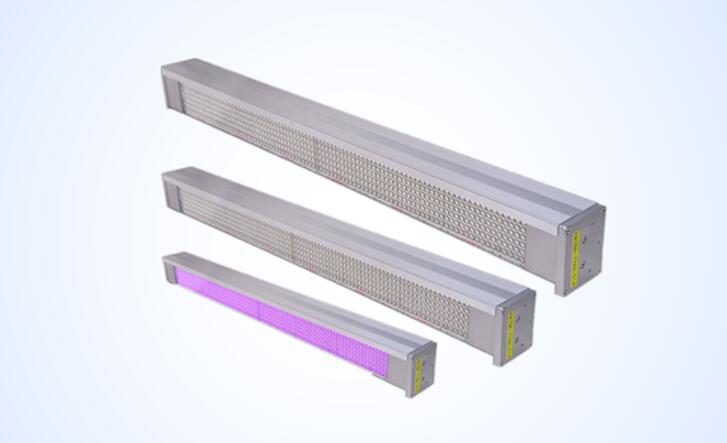

UV varnish is a kind of transparent paint, also called UV varnish. Its function is to spray or roll on the surface of the substrate, after being irradiated by the UV lamp, it will turn from liquid to solid, and then achieve surface hardening, its scratch and scratch resistance effect, and the surface looks bright, beautiful, and round texture .

Precautions for UV varnish

1. The normal use temperature of UV varnish is 50-55℃. When using at low temperature in winter, the UV varnish needs to be heated in a constant temperature water area to make the viscosity reach the design viscosity, which is beneficial to the leveling and rapid curing of UV varnish. .

2. When UV varnish passes through the UV lamp irradiated area, the best temperature should be 50-60℃, because UV varnish cures quickly at this temperature and has strong adhesion after curing. In other words, the lower the temperature is not the better under the UV lamp. Some manufacturers have poor adhesion and poor leveling when glazing at low-temperature workshops in winter. This is the main reason.

3. The glazing machine should be placed in a location where the sun can not be directly exposed, otherwise the UV varnish will be cured on the coating roller under the action of the ultraviolet light in the sun. If you can't avoid direct sunlight, you should also use red and black curtains to block the sun's rays.

4. The UV varnish scraped off during glazing will bring the ink that has been printed on the substrate to the UV varnish on the glazing machine to make the glazing oil colored. However, after filtration and sedimentation, these varnishes can still be used and do not need to be thrown away.

5. With the development of technology, the irritation of UV varnish has been greatly reduced. However, during the glazing operation, if the skin touches the UV varnish, it should be washed off immediately with soap and water, otherwise the skin may be swollen and blistered.

6. The viscosity of UV varnish differs according to the type of varnish, and special varnish should be selected according to the model of the varnish. If the viscosity of UV varnish is not up to the required viscosity of the polisher, it can be removed with a thinner or thickened with a thickener. But after such adjustment, the curing speed, brightness and adhesion of UV varnish will be lost.

Precautions for UV varnish- how to use uv varnish correctly more information

Precautions for UV varnish- how to use uv varnish correctly business discussion contacts