Solution to the problem of uv varnish in printing (C)

Solution to the problem of uv varnish in printing (C)

(Continued to last article)

Solution to the problem of uv varnish in printing

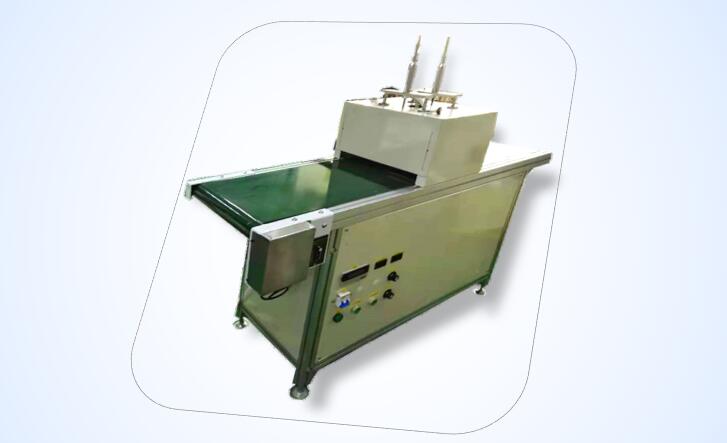

UV varnish is a kind of transparent paint, also called UV varnish. Its function is to spray or roll on the surface of the substrate, after being irradiated by the UV lamp, it will turn from liquid to solid, and then achieve surface hardening, its scratch and scratch resistance effect, and the surface looks bright, beautiful, and round texture . There are still some problems in the process of practical use, but we can provide corresponding solutions for the use of UV varnish.

C. The UV varnish on the surface of the printed material paper cannot be applied, and there are similar spots like flowers, the main reason for this problem

1. The viscosity of UV varnish is too small and the coating is too thin.

2. The content of diluting oil or dry oil in the ink is too high

3. The ink surface has been crystallized

4. Too many anti-sticking materials (silicone oil, powder spraying) on the ink surface

5. The wire of the glued anilox roll is too thin

6. The problem of construction technology (the technical staff is not good enough)

Solution to the problem of uv varnish in printing (C) as below

Solution: For products that require UV glazing, corresponding measures should be taken when printing to create certain conditions: UV varnish can be coated thicker, if necessary, primer or special varnish formula. Look for high-quality UV varnish, and don't use less-quality UV varnish. Cooperate with trusted ink manufacturers.

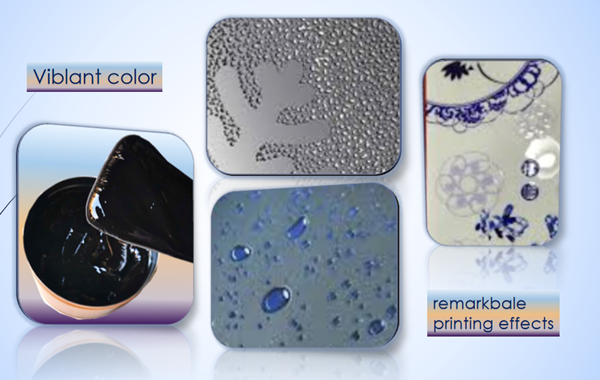

Solution to the problem of uv varnish in printing (C) in practical solved picture with beautiful refinshing effects

(To be continued)

Solution to the problem of uv varnish in printing (C) communication contacts