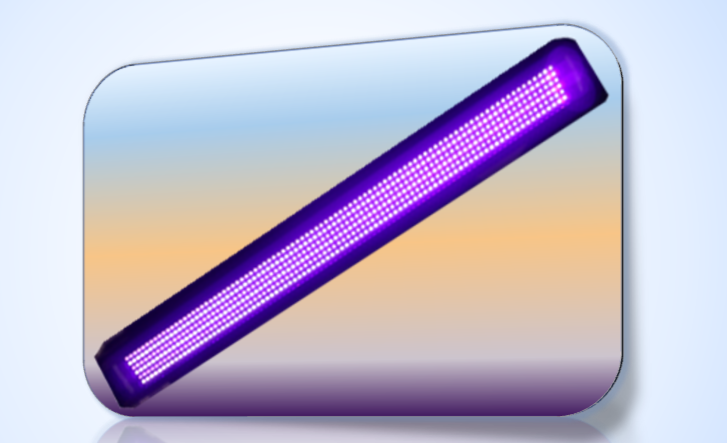

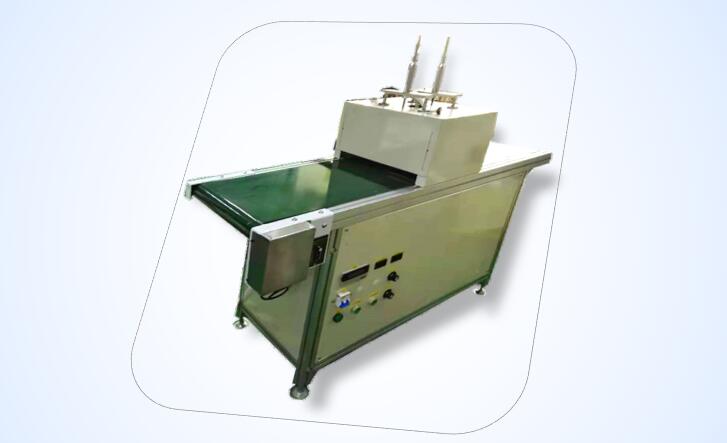

LED UV Systems equipment for Sheetfed Offset Printing

LED UV Systems equipment for Sheetfed Offset Printing

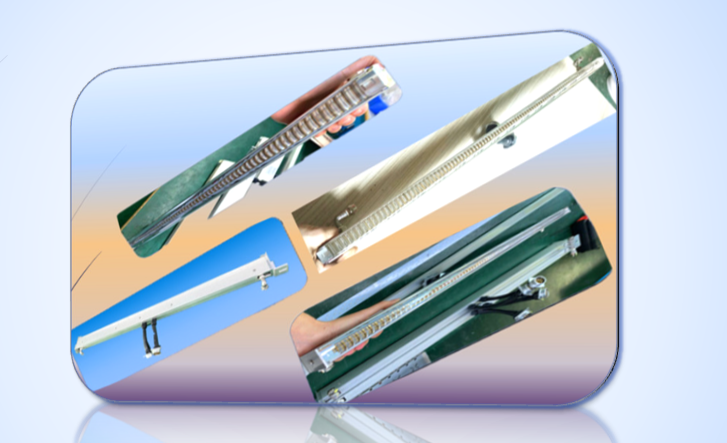

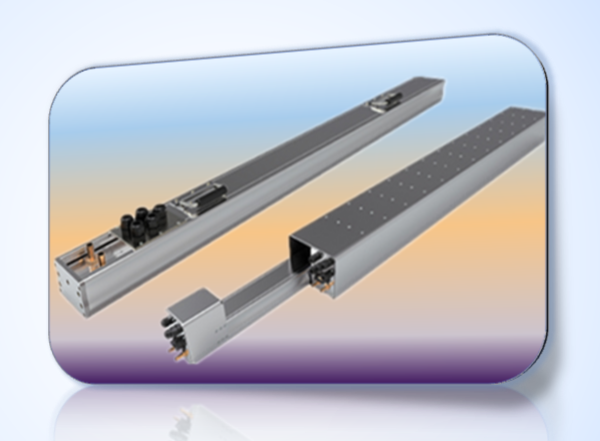

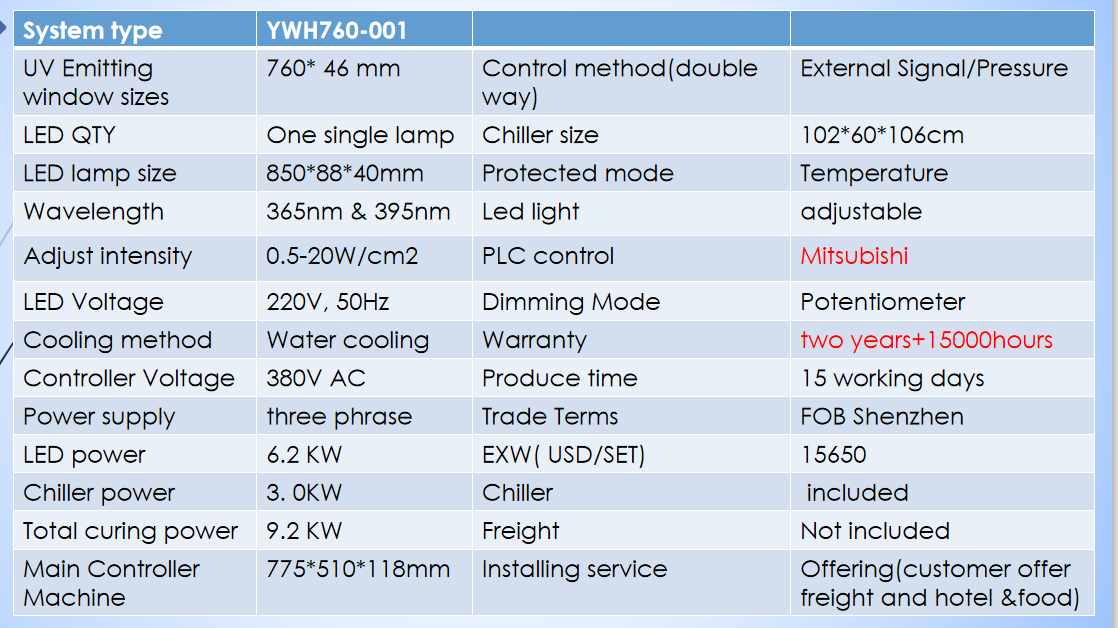

This led uv curing system specially designed for Heidelberg/Roland/KBA/Mitsubishi/Komori offset printing press. Its our updated new verson most reasonaable masterwork.

LED-UV curing offers numerous advantages over traditional printing methods.

1, Cold light source ─ ─ small heat radiation, no infrared light, wide adaptability.

2, Fast and efficient ─ ─ instant start, curing speed, higher performance

3, Long life - more than 30,000 hours;

4, Instant switch - switch on at any time without preheating;

5, Economy - instant switch, high production efficiency, low energy consumption

6, Environmental protection - no ozone discharge, mercury pollution;eco-friendly, instant drying.

7, Safety - no shortwave, low voltage, cold light source;

8, Easy to operate ─ ─ easy to use simple, low operating costs.

9, Electricity cost saving—80% saving comparing to traditional mercury lamp.

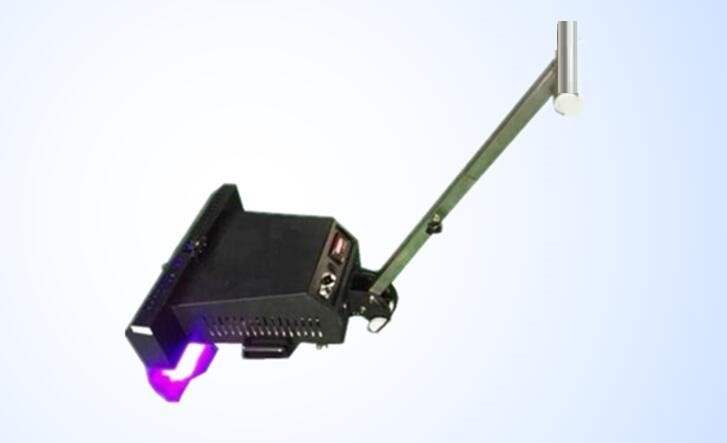

10, Remote controlling——Smart PLC controlling system .

11, Low VOC.

12. VOC-free LED-UV inks, Perfect Equipped with our harmless ink.

The principle of UVLED curing means that under the irradiation of ultraviolet light, a photoinitiator absorbs photons of a specific wavelength to reach an excited state to form free radicals or cations, and then through the transfer of energy between molecules, the polymerizable prepolymer and photosensitive monomer are changed In an excited state, charge transfer complexes are generated. These complexes are continuously cross-linked and polymerized, and solidify in a very short time to form a three-dimensional network structure of high molecular polymers.

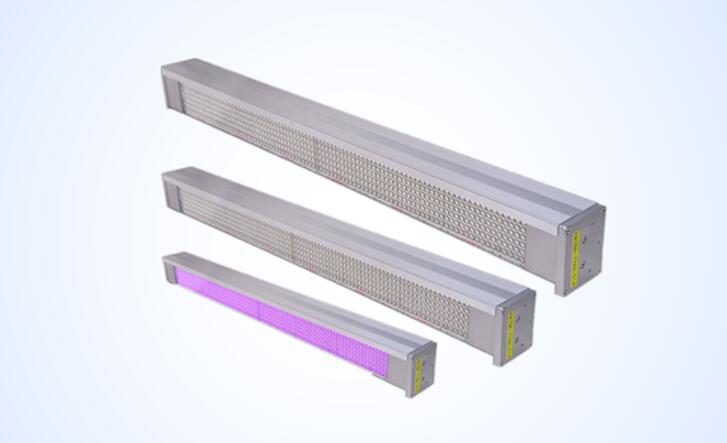

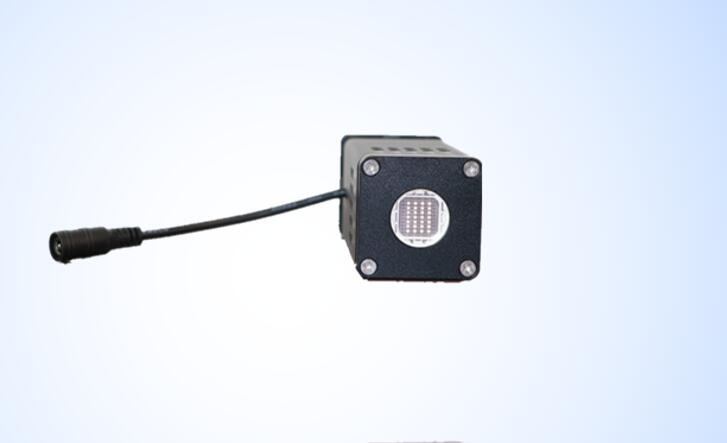

One controller with five led uv lamp provide your offset printing production line most wanted led uv drying system.

Vistiing More led uv system for Sheetfed Offset Printing Products.

LED UV Systems equipment for Sheetfed Offset Printing contacts