LED UV Curing for Heidelberg Sheetfed Offset Printing Presses

LED UV Curing for Heidelberg Sheetfed Offset Printing Presses

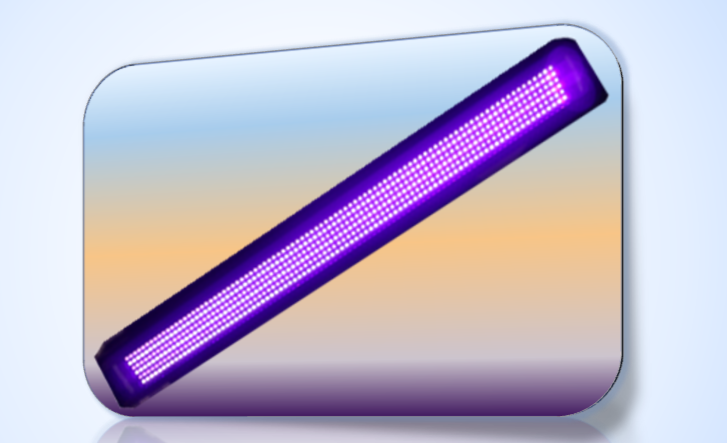

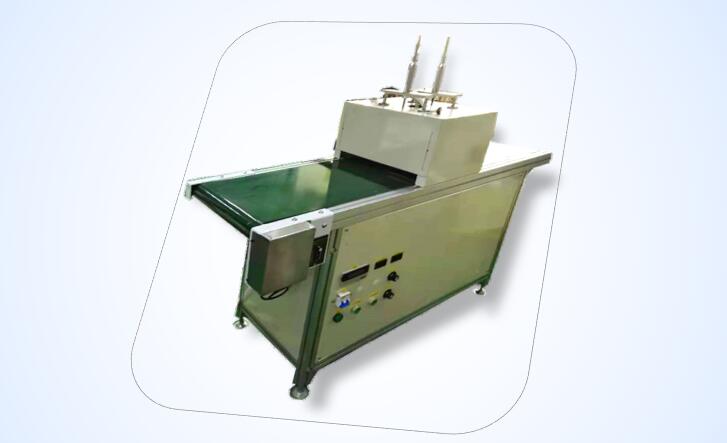

LED UV Curing systems bring energy-efficient, heat-less, solid-state curing to sheetfed offset heidelber printing press.

Gone are the printing workshops that used to be full of powder, expensive infrared/hot air dryers, marking problems and waiting for the paper to dry.

So far, the led uv system is a leader in the printing industry in providing high strength, flexibility and fast return on investment. By installing and applying practical operations on different types of printing machines in the printing industry in recent years, our LED UV Curing offset printing solutions can help customers obtain amazing printing curing speed and results

Our LED UV Curing system can perform printing and perfect printing at extremely high printing speeds in sheetfed offset Heidelberg printing. The result has excellent epoch-making significance that breaks the tradition and provides excellent results for immediate post-production steps (such as cutting, scoring and making).

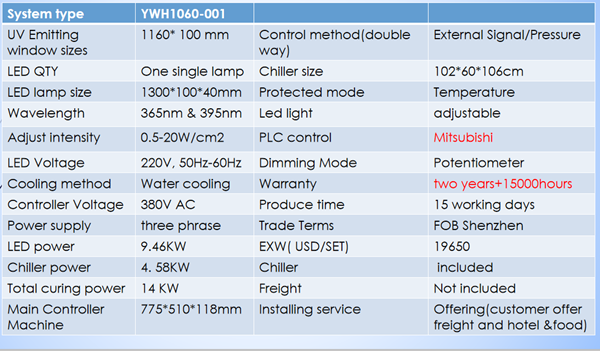

LED UV Curing for Heidelberg Sheetfed Offset Printing Presses Technology data

LED UV Curing Advantages

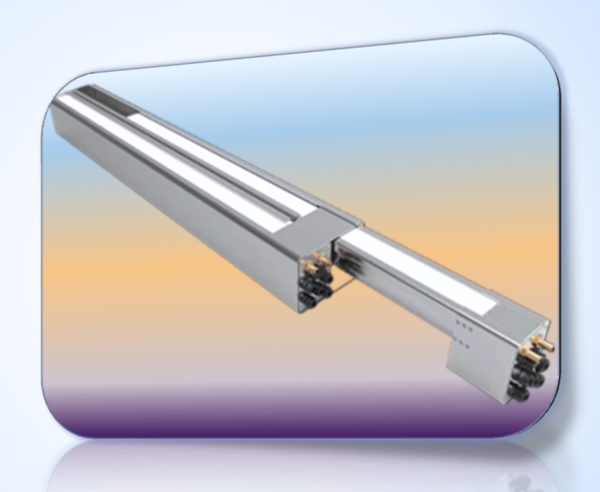

1.LED UV curing achieves the highest UV intensity, to support the fastest printing speeds

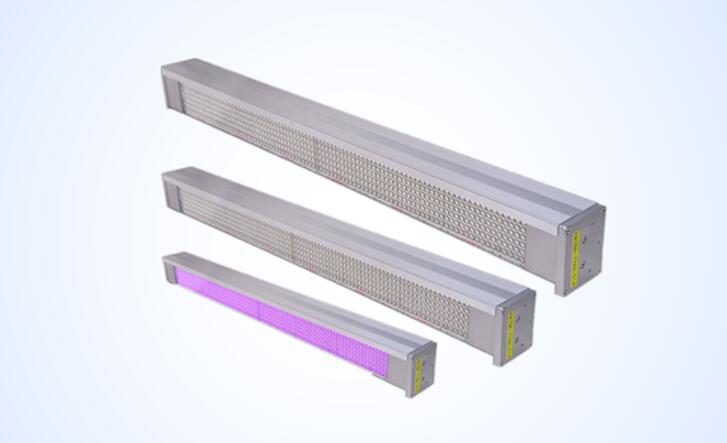

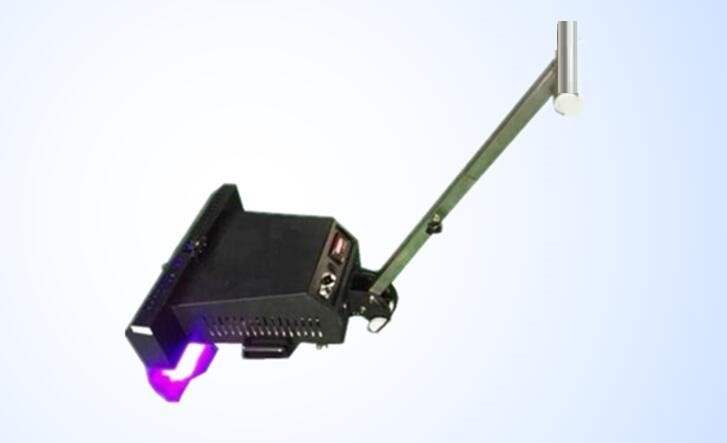

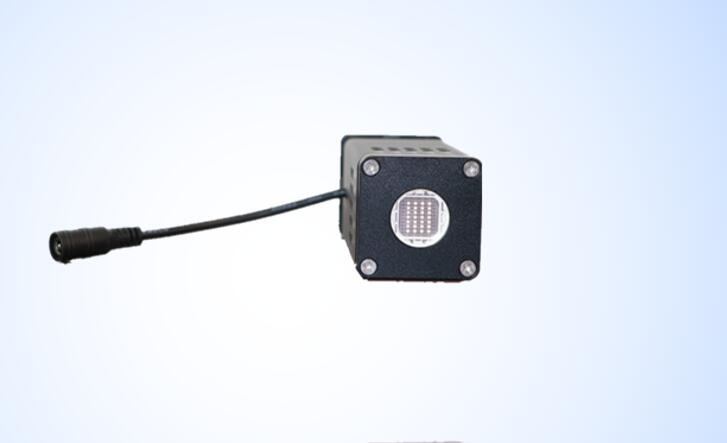

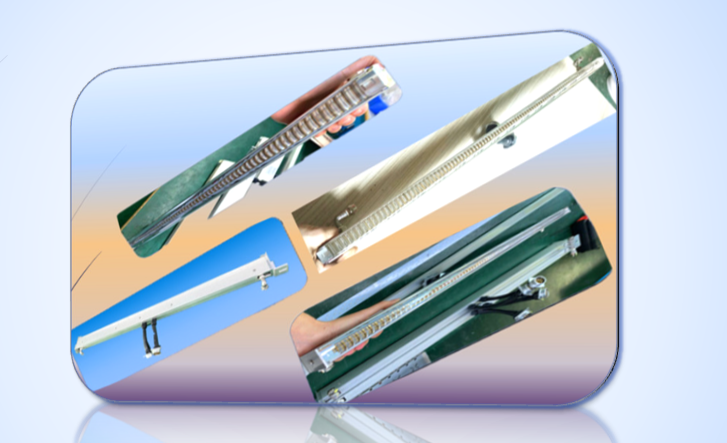

2. LED UV curing Compact design fits almost all press types

3.LED array is fully sealed for easy cleaning and resilience to ink and dust ingress

4. LED UV Cold light source ─ ─ small heat radiation, no infrared light, wide adaptability.Direct UV path with no UV lost in reflections.

5.Fast and efficient ─ ─LED UV curing lamp instant start, curing speed, higher performance

6. LED UV lamp with movable between print units function.

7.Continuous remote monitoring of lamps/LEDs and smart PLC ensures the most reliable operation and fastest support for any manufacturer.

8.Uniform LED UV light output across the curing area.

9. Long life -LED character with more than 30,000 hours lifetime.

10.Modular Lamp Array (MLA) gives customisable mounting options

11.Economy - instant switch, high production efficiency, low energy consumption

12, Environmental protection - LED UV curing light without ozone discharge, mercury pollution; eco-friendly, instant drying.

13, Safety - LED UV equipment without shortwave, low voltage and it is cold light source;

14, Easy to operate ─ ─ Led uv system easy to use simple, low operating costs.

15, Electricity cost saving—LED UV curing systems 80% saving, comparing to traditional mercury lamp.

16, VOC-free LED-UV inks, Perfect Equipped with our harmless ink.

We offer you: High quality: the led uv curing system quality controlled by our quality control people both in the production line and in the quality rooms before departure .

Competitive prices: we do everything to get the best prices for our clients Transport discounts: we understand that transport is a very important component of the final price, and offer discounts on rates.

Customized approach to your needs: our sales team will work hard to meet your requirements and will follow every detail of your needs Reliability, quickness of solutions, transparency . We highly value our clients!

LED UV Curing System Applications:

Heidelberg / Roland /KBA / Komori Offset Printing ect.

Visiting More LED UV Curing products.

LED UV Curing for Heidelberg Sheetfed Offset Printing Presses Contacts