High quality LED Printing Ink Offset Class-leading UV LED PVC Ink

High quality LED Printing Ink Offset Class-leading UV LED PVC Ink

Printing process technology that incorporates LED-UV curing offers numerous advantages over traditional printing methods. LED-UV in Offset Lithographic Printing.UV Offset led printing ink for offset printing PVC,paper press, Low Energy Consumption UV characteristic of low energy led ink cure systems offer easiy printing soltuois in offset printing job .

High quality LED Printing Ink Offset Class-leading UV LED PVC Ink workshop equipment with quality producing machine, strictly opperating processing , skilled starffs.

LED printing ink Fast curing speed: Under ultraviolet light, offset printing UV ink can achieve secondary drying. Packaging printing usually requires a larger printing surface and a higher printing density. Therefore, the ink volume must be increased. Then the problem of drying becomes very important. If the ink does not dry well, it usually affects production efficiency. Our offset printing LED UV curing system and offset printing LED UV INK synthesis solutions solve this problem. UV offset led printing inks used for offset printing PVC and paper machines have experienced 5 years of practical application and gradual improvement in technology, which proves that LED The uv curing system and LED pritning ink solutions are 100% low energy consumption, fast and environmentally friendly.

High quality LED Printing Ink Offset Class-leading UV LED PVC Ink Advantages:

1. LED Printing Ink Fast drying, good adhesion force, Good printability,flexibility and gloss, good performance at bond resistance and anti-scratch.

2. Superior printability and recoatability, high brightness and high chroma, fine and smooth without misting.

3. Excellent chemical resistance, resist scrubbing of most organic solvent, alkali, acid oil.

4, 75% reduction of energy consumption compared to the conventional UV printing

5, LED uv offset ink/ lamp has longer life than the existing lamp

6, LED Printing Ink Stability on press.

7, No heating and ozone emission from the lamp

8, High Adhesion type led printing ink.

9, Mercury free lamp

10, Distinguished curing property-Curing property under the condition of LED lamp is quite close to conventional UV ink.

11. Various Application range depending on the technical requirements for led uv offset ink printing such as adherence, rub-resistance, anti-scratching, Anti-yellowing.

12, Led Printing ink more Environment friendly

13, Excellent in de-inking and suitable for recycling.

LED Printing Ink Application:

PET, gold and silver cardboard, Metallized paper, inkjet paper,alcohol and tobacco packaging, cosmetic packaging products, electronic products packaging, food packaging, pictures, etc.

High quality LED Printing Ink Offset Class-leading UV LED PVC Ink Packaging and trading terms

Packing:1KG/ can or 2kg /can,12 cans in one carton box with protections, intenation standard box.

Shelf life:12 months

SHENZHEN, OR GUANGZHOU

Lead Time :Shipped in 5 days after payment

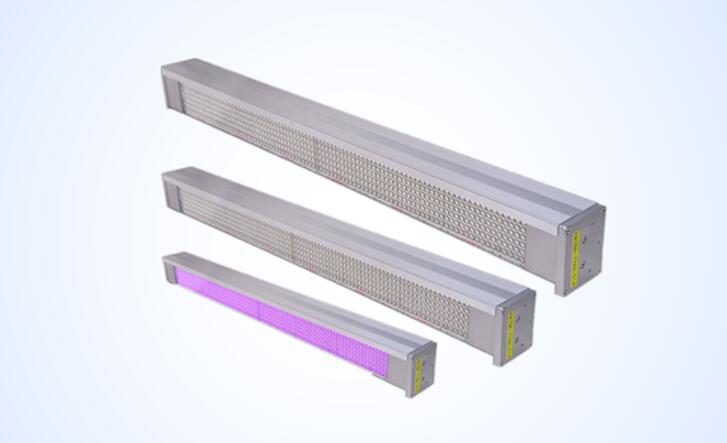

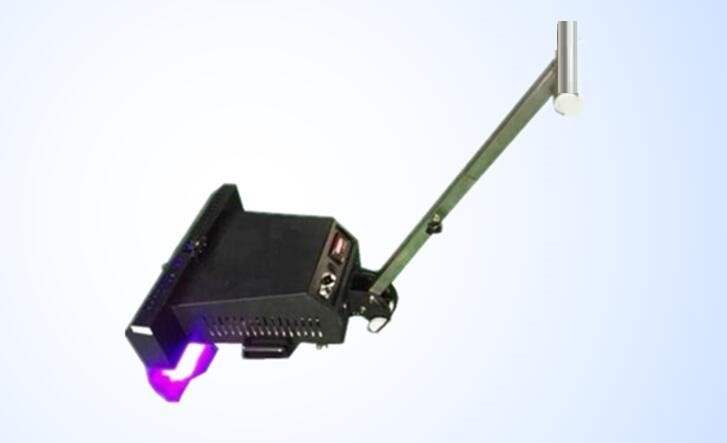

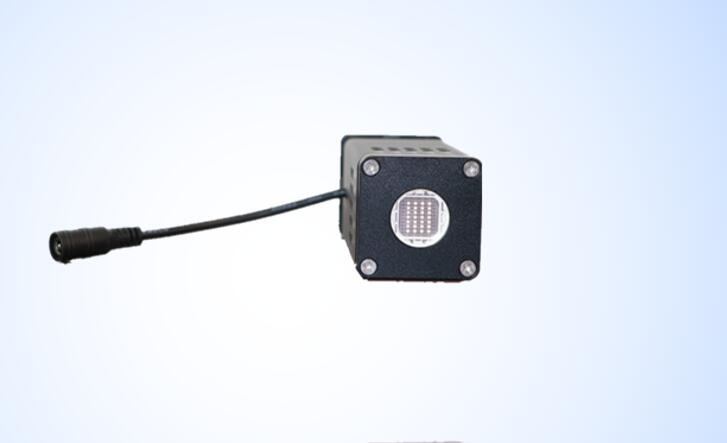

Our led uv curing system going through five years practical application together with our led uv ink proven to be best offset pritning solutions in printing field.

Use our led uv lamp to cure our led uv ink perfect work, we ensure that led cure that ink completely , if not , refund your payment.

More Led printing ink offset pvc ink cure application productions

High quality LED Printing Ink Offset Class-leading UV LED PVC Ink contacts