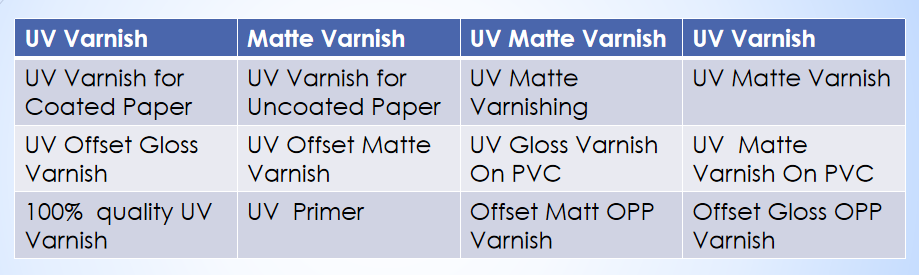

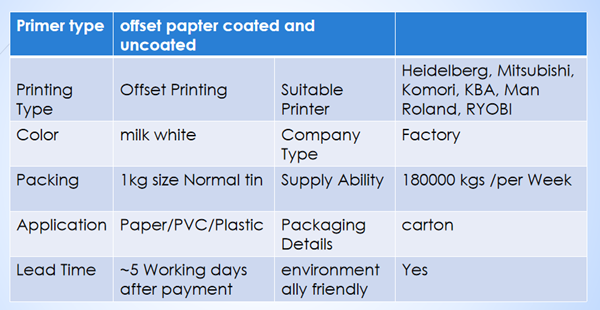

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper

UV Primer for paper coating well used in printing industry. It has medium viscosity, low toxicity, and good adhesive property. Application with UV roller varnish provides the best adhesive property for paper roller coating.

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper relative product date sheets

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper application comparing to traditional coating description:

The traditional curing of coatings usually involves heating or physical drying to remove the solvent in the polymer solution to obtain a hardened paint film.

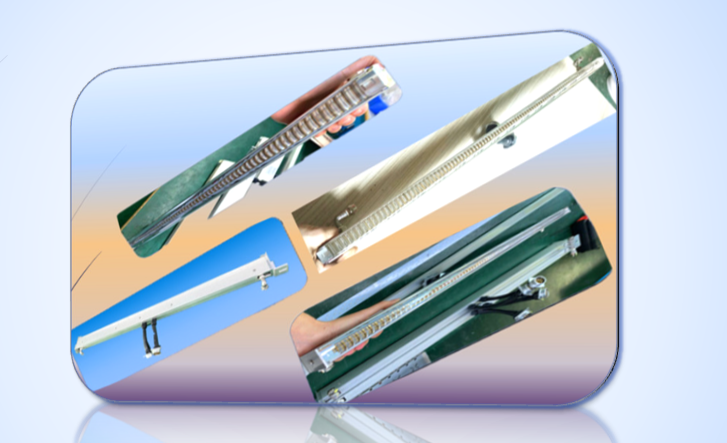

UV curing uses the energy of ultraviolet light to initiate polymerization and cross-linking reactions between low-molecular prepolymers or oligomers in the coating and monomer molecules as reactive diluents to obtain a hardened paint film, essentially by forming The chemical bond achieves chemical drying.

Energy saving, high energy utilization rate;

No solvent discharge, safe and pollution-free;

Fast curing speed and high production efficiency;

Can be coated with heat-sensitive substrates;

High film quality and excellent coating performance

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper application partner

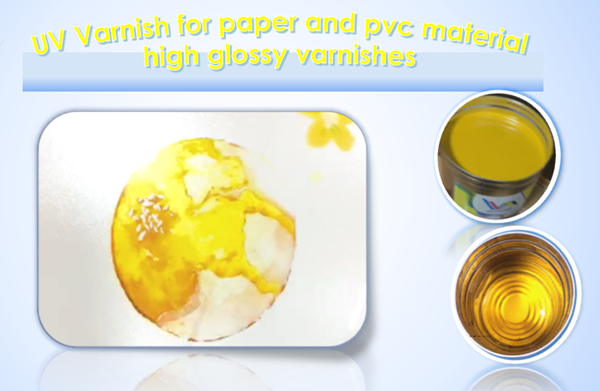

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper product in real printing application effects

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper benifits in offset printing application and disadvantages:

Advantages of UV primer:

1. Long pot life

2. Excellent yellowing resistance

3. Good hardness and high transparency

4. Very high solid content

5. It is currently one of the most environmentally friendly paint varieties

6. High efficiency and low coating cost (normally half the cost of conventional coating, dozens of times the efficiency of conventional coating).

7. Increase the adhesion between the coating and the surface of the plastic substrate

8. Seal the residue in the substrate to ensure the quality of the coating

9. Improve the flatness of the substrate surface to ensure the mirror coating effect

Relative disadvantages of UV primer :

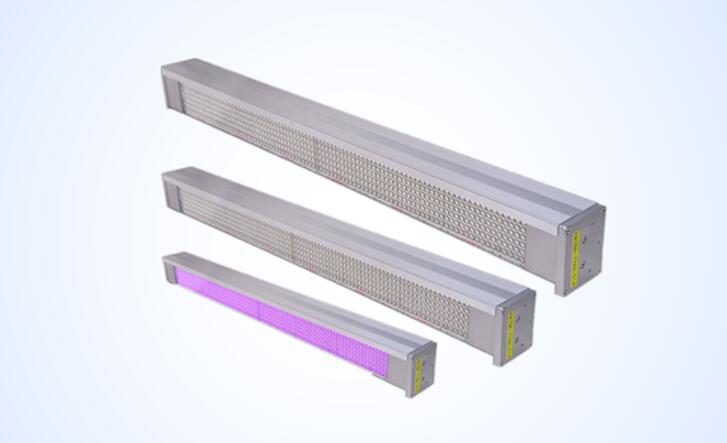

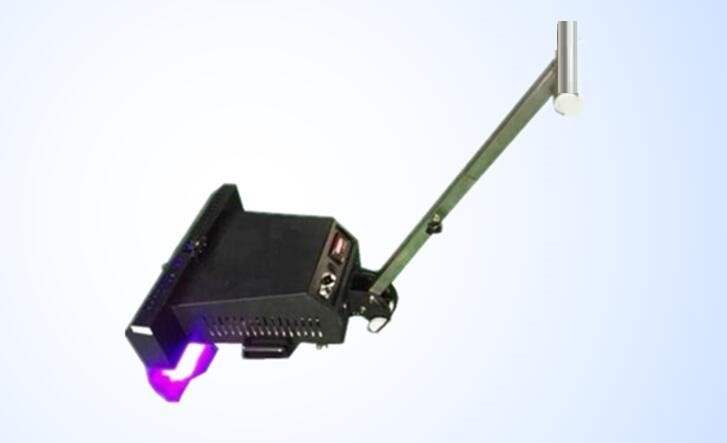

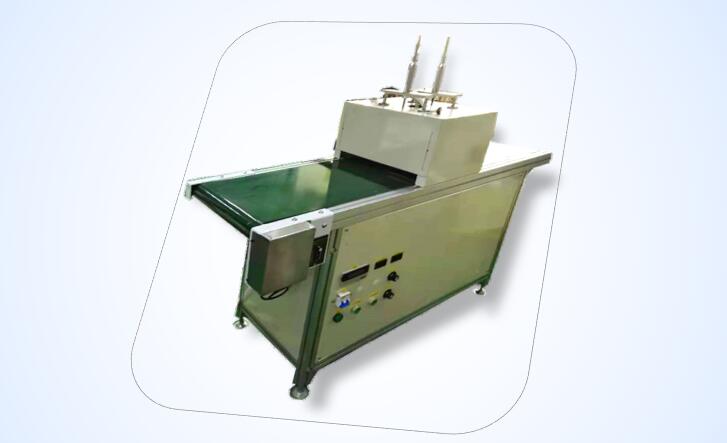

1. Large investment in various equipments of UV coating production line is required.

2. There must be a sufficient supply of goods to meet its production needs. Continuous production can reflect its efficiency and cost control.

3. Sensitive to dust (strict construction environment requirements)

4. Irregular objects are not easy to operate

5. The price is slightly more expensive

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper packaging details

More primer product infromation

Primer for Coatings on - PE, PP, ABS, PVC UV Coated Paper more product business discussing contact